Thermography for Solar Panel Inspection Using Drones comes into play. By combining thermal imaging with aerial drone technology, solar field operators can quickly detect issues, prevent power loss, and boost efficiency—all without setting foot on a rooftop or solar array.

As India moves toward a greener energy future, solar power plays a critical role. But maintaining large solar farms efficiently is a challenge—especially when it comes to identifying faulty panels or underperforming modules.

What is Thermography in Solar Panel Inspection?

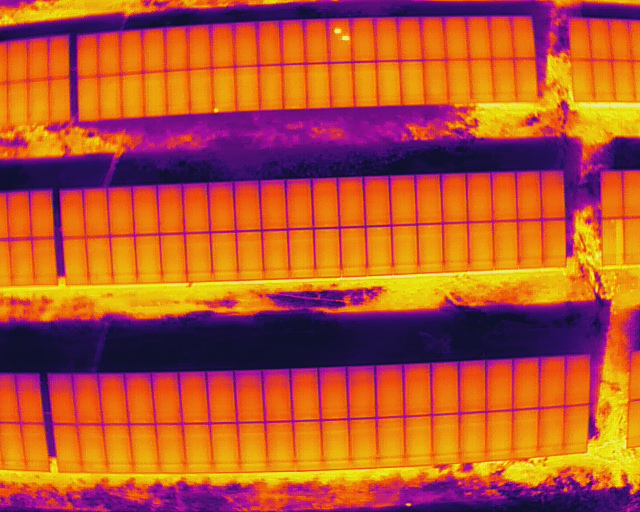

Thermography involves capturing infrared images that show surface temperature variations. When applied to solar panels, it helps detect:

- Hotspots (damaged cells or modules)

- Diode failures

- Interconnection faults

- Soiling or shading issues

- Degraded panels

These issues may not be visible to the naked eye but drastically affect performance and safety.

Why Thermography Matters in Solar Panel Inspection?

Thermal imaging, also known as infrared thermography, detects heat patterns emitted by objects. When applied to solar panels, it helps identify:

- 🔥 Hotspots caused by damaged cells

- 🔌 Faulty connections or bypass diodes

- 🌫️ Dirt buildup causing thermal imbalances

- ⚡ Inverter and junction box overheating

Why Use Drones for Thermographic Solar Panel Inspection?

Traditional inspection methods require technicians to walk through fields with handheld thermal cameras—a time-consuming and error-prone process.

Drones provide a smarter, more scalable solution:

- Speed: Inspect hundreds of panels in minutes

- Safety: No climbing or physical contact required

- Accuracy: High-resolution thermal + visual data

- Data Efficiency: Immediate insights for O&M teams

Project Workflow

- Pre-Flight Planning

- Drone Selection & Payload

- Data Collection

- Data Processing

- Reporting & Analysis

Benefits of Drone Thermography for Solar Farms

- Maximized Efficiency: Fix faulty panels faster

- Preventative Maintenance: Stop small issues before they scale

- Scalability: Ideal for utility-scale solar farms

- Regulatory Compliance: Easier audits and documentation

- Cost-Effective: Fewer personnel and quicker inspections

Use Cases

- Utility-scale Solar Parks

- Commercial Rooftops

- Agricultural Solar Arrays

- Floating Solar Farms

The Future of Solar Thermography with Drones

- AI Integration: Automated detection and classification of defects

- Real-Time Monitoring: Live insights through edge computing

- Autonomous Inspections: Scheduled patrols with minimal human input

- Digital Twins: Build 3D models with thermal overlays for historical analysis

Conclusion

Thermography for Solar Panel Inspection Using Drones is revolutionizing how we maintain and optimize solar installations. It’s fast, precise, and incredibly efficient—empowering solar companies, EPCs, and energy utilities to maximize performance, extend panel life, and cut downtime.

As India’s solar footprint expands, drone thermography isn’t just helpful—it’s essential.