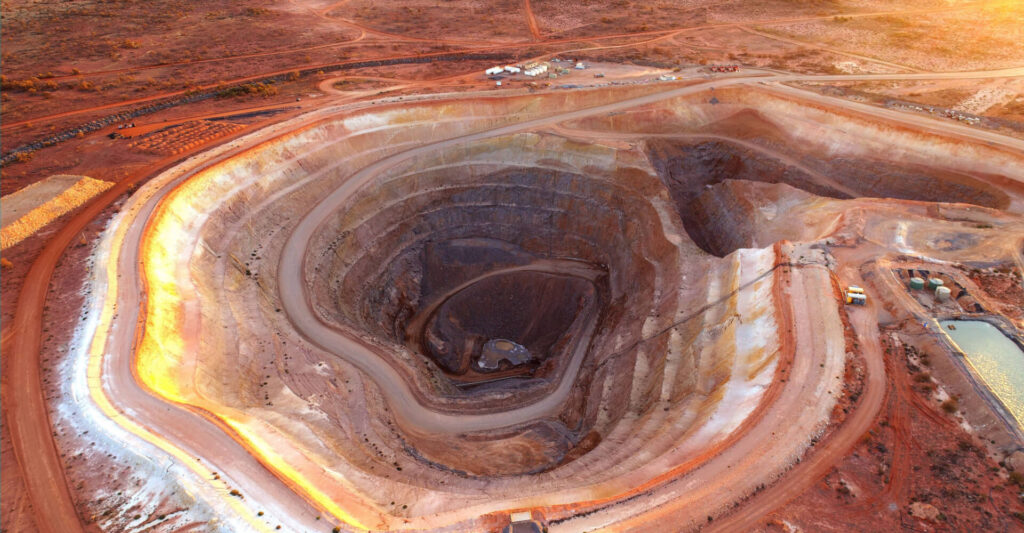

Mining is no longer just about digging deep—it’s about digging smart. The LiDAR Survey of Mines has emerged as a cutting-edge technology that’s reshaping how modern mining operations are planned, executed, and managed. With unmatched precision and speed, LiDAR is enhancing everything from terrain modeling to volume estimation and safety analysis.

Whether for open-pit mines, quarries, or complex terrain extraction, LiDAR (Light Detection and Ranging) is now the go-to tool for digital mine mapping.

What is a LiDAR Survey?

LiDAR is a remote sensing method that uses laser pulses to measure distances to the Earth’s surface. By sending thousands of light pulses per second and measuring the time they take to return, LiDAR creates accurate 3D representations of terrain and objects.

There are two main platforms for LiDAR in mining:

- Aerial (Drone or Helicopter-mounted)

- Terrestrial (Tripod-mounted on ground)

Benefits of LiDAR in Mining:

- High Accuracy: Captures detailed terrain and volumetric data with centimeter-level precision.

- Speed: Covers large, rugged areas in a short time.

- Safety: Reduces the need for personnel in hazardous zones.

- 3D Modelling: Creates digital terrain models (DTMs), surface models (DSMs), and volumetric calculations.

- Vegetation Penetration: Can map bare earth beneath dense foliage or debris.

Applications of LiDAR in Modern Mining

- Topographic Mapping of Mine Sites

- Overburden and Pit Volume Calculation

- Stockpile Monitoring & Reconciliation

- Slope Stability and Surface Change Detection

- Environmental Impact Studies & Land Restoration

- Underground Tunnel Mapping (with mobile LiDAR)

The LiDAR Survey Workflow in Mining

- Mission Planning: Define survey boundaries and prepare flight paths.

- Data Acquisition: Drone or airborne LiDAR collects 3D data via laser pulses.

- Post-Processing: Software like TerraScan, Global Mapper, or Pix4D converts point clouds into usable 3D models.

- Analysis & Reporting: Volume reports, elevation profiles, contour maps, and slope studies are generated for use by mining engineers and planners.

Real-World Impact

Mining companies across India and globally are adopting LiDAR surveys for:

- Coal mines in Chhattisgarh & Jharkhand

- Limestone and bauxite mines in Odisha

- Iron ore mapping in Karnataka

- Aggregate quarries and sand mining in riverbeds

The result? Better resource management, regulatory compliance, and cost-efficiency.

Conclusion

LiDAR has become a cornerstone of modern mine surveying. With its ability to quickly and safely generate precise 3D models, this technology helps miners improve planning, reduce risk, and increase productivity. As the industry embraces automation and digitalization, LiDAR surveys will remain a critical tool in unlocking efficiency and sustainability in mining.